The Making: Calyx Solitaire Ring

June 26, 2024

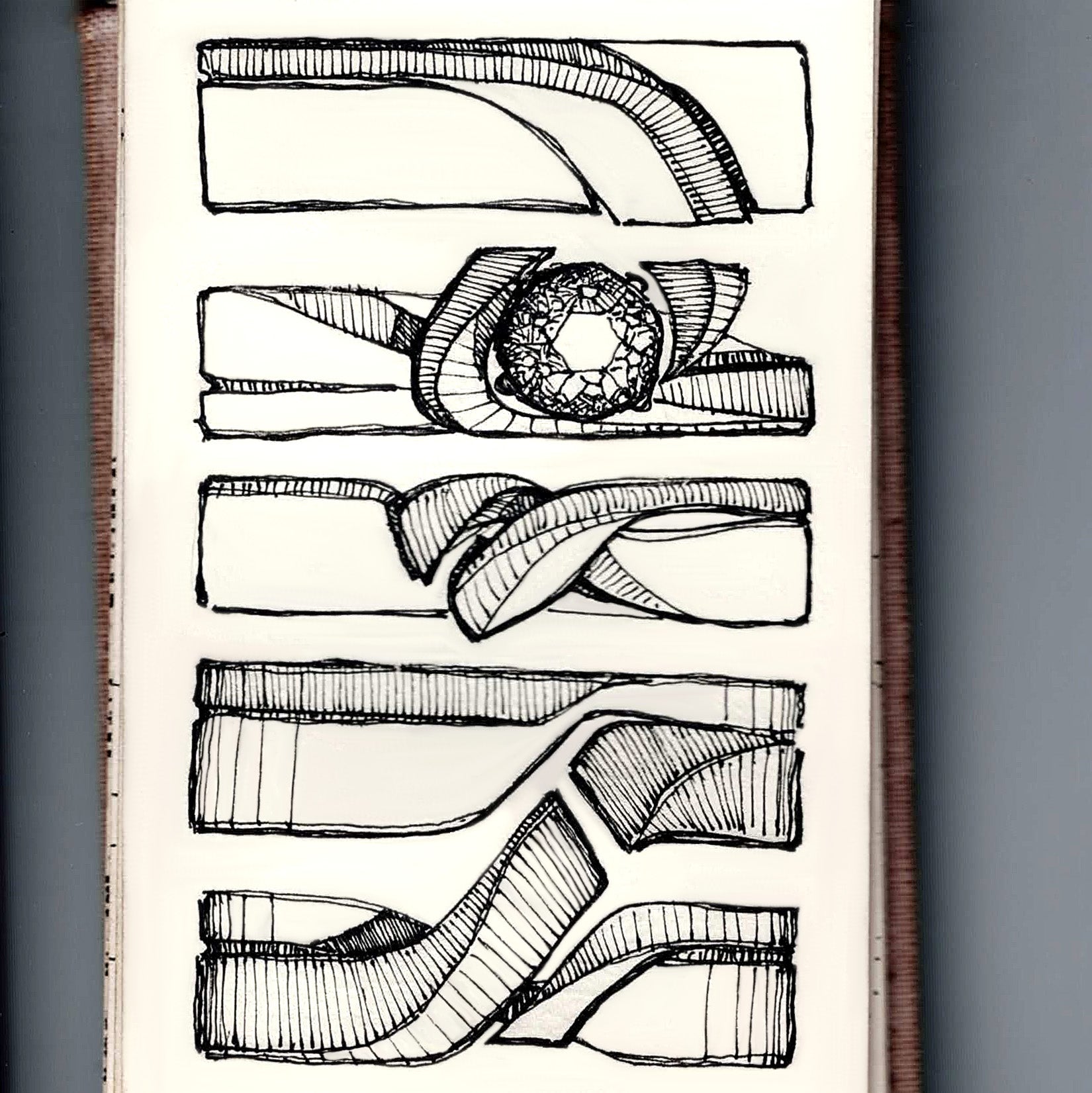

The Making of Calyx

Get behind the scenes insight on the making of Calyx ring

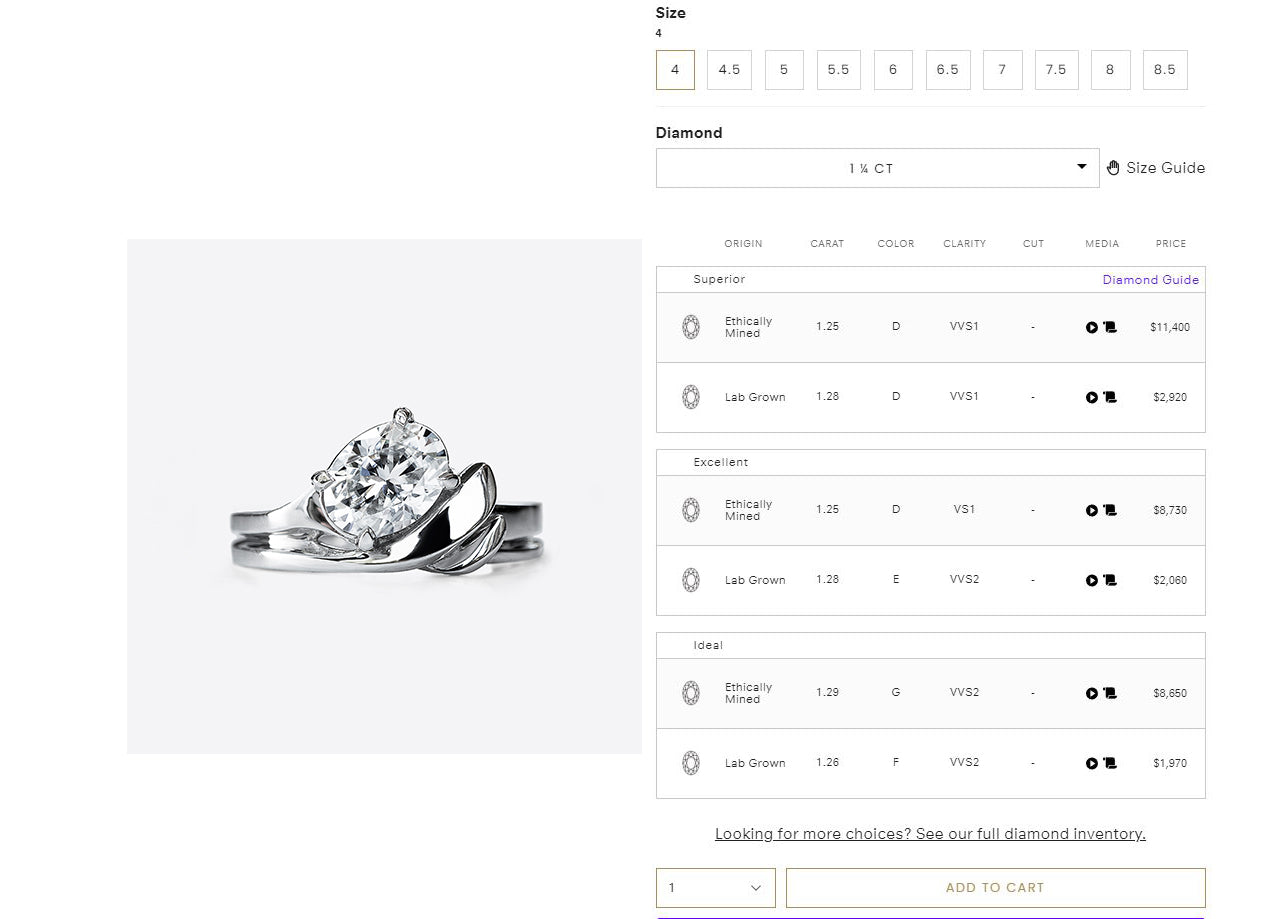

The Calyx Solitaire Ring is available online now.

Make your custom order today and be among the first to acquire this stunning solitaire ring!